Smart Manufacturing

Product StrategyHow might we empower manufacturing teams to take strategic actions through better machine data?

Challenge

Manufacturing teams need effective ways to reduce costs and improve the efficiency of their plants. 82% of companies have experienced unplanned downtime over the past three years.

Approach

We conducted foundational research on manufacturing sites with maintenance, production, quality, and management department participants. Through different stages of prototypes and iteration, we understood key features and possible competitive advantages. Amongst them was the discovery that manufacturing teams aren’t only looking for machine data but also a way to empower their teams to take strategic actions. If this were a Fitbit for machines, users wouldn’t want data; they want to be empowered to make better decisions and form habits.

We used a Guerrilla approach to research. We presented a stand at trade shows to pitch the idea at anyone interested and guided them through a card sorting exercise to understand what features would be most relevant and why.

Outcome

Cogniplant is a Software as a Service solution that empowers maintenance teams to take control of their operations. Through accurate data about equipment downtime due to failures or faults, smarter preventive actions can be taken and overall operations can be optimized.

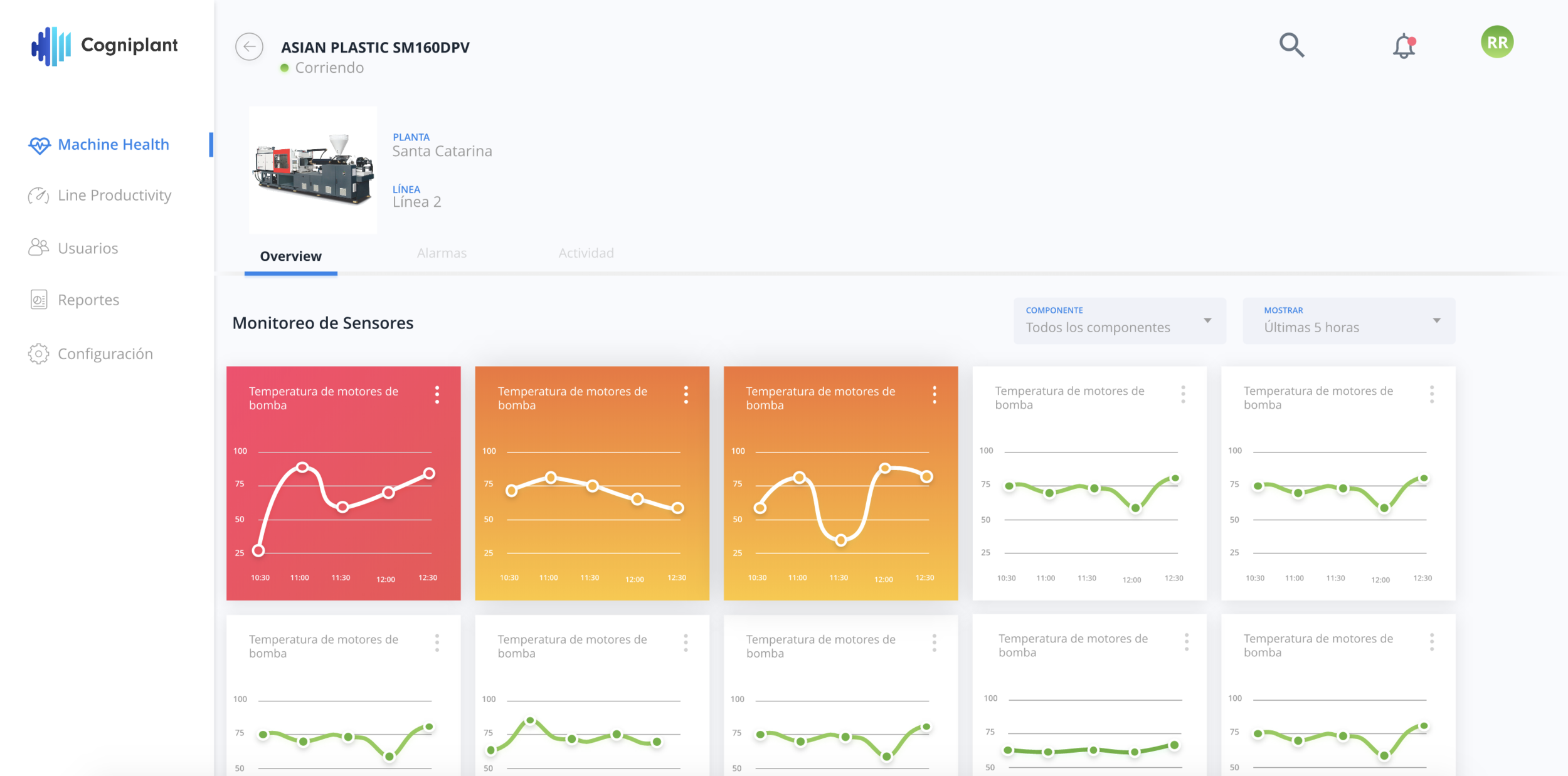

With the Machine Health monitor, maintenance teams can have greater control of their equipment and take preventive actions.

Realtime conditions

Configurable alarms

Maintenance activities log

The Minimum Viable Product of our solution is now live in manufacturing plants across the plastic molding and food processing industries. A key pivot in our solution process was shifting from designing hardware to creating a service for third-party hardware integration. Designing with IoT means being conscious of the different protocols OEMs integrate into their equipment and being able to scale in spite of their limitations.

Our team is now developing a predictive maintenance model based on the data captured from our first launch. Our roadmap for product innovation capitalizes on IoT + AI through a human-centered lens of the manufacturing process.